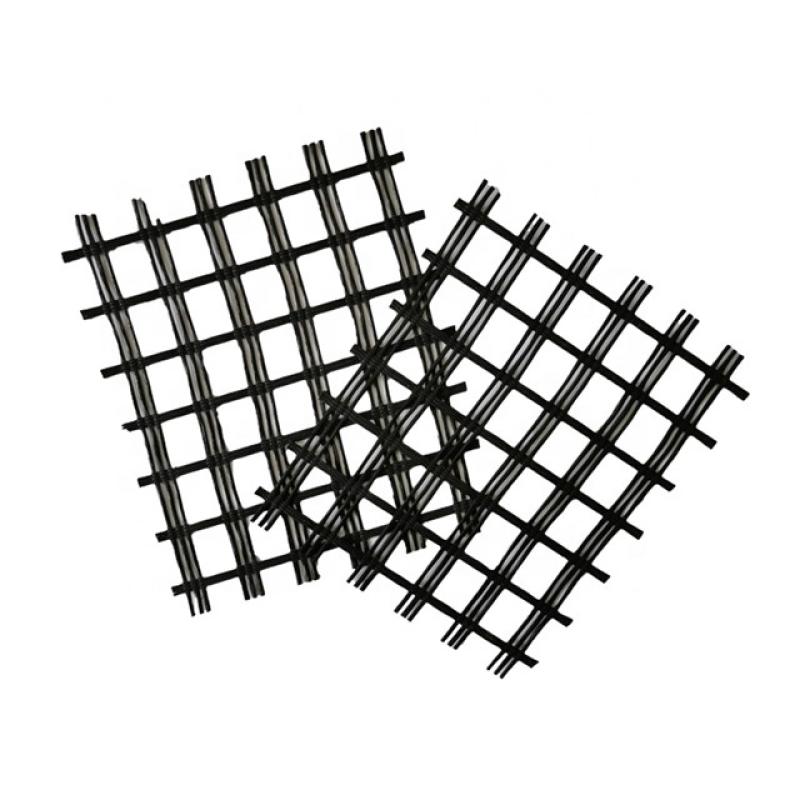

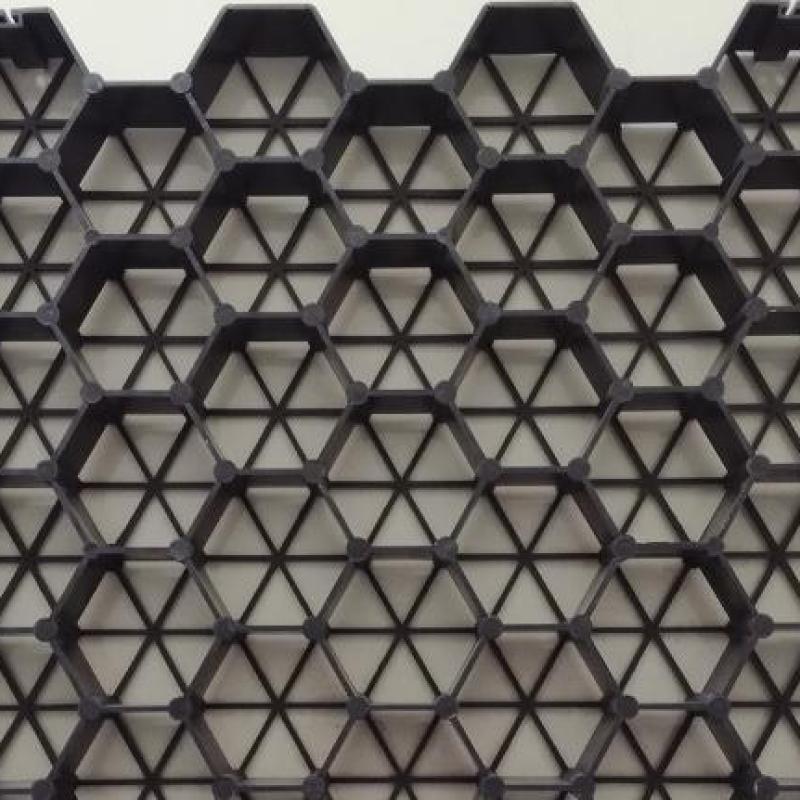

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Contacter maintenant

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Contacter maintenant

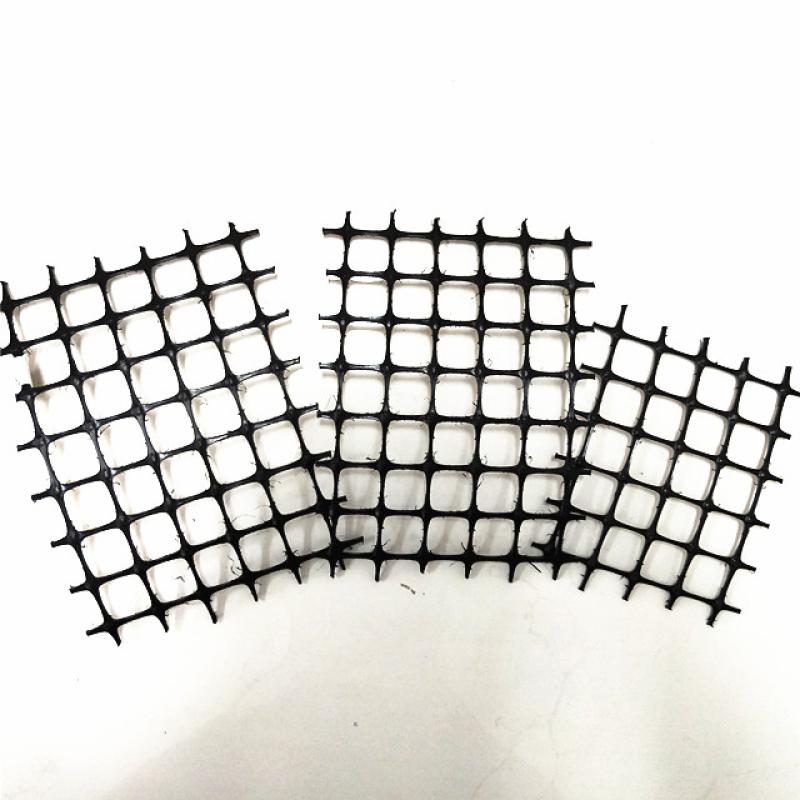

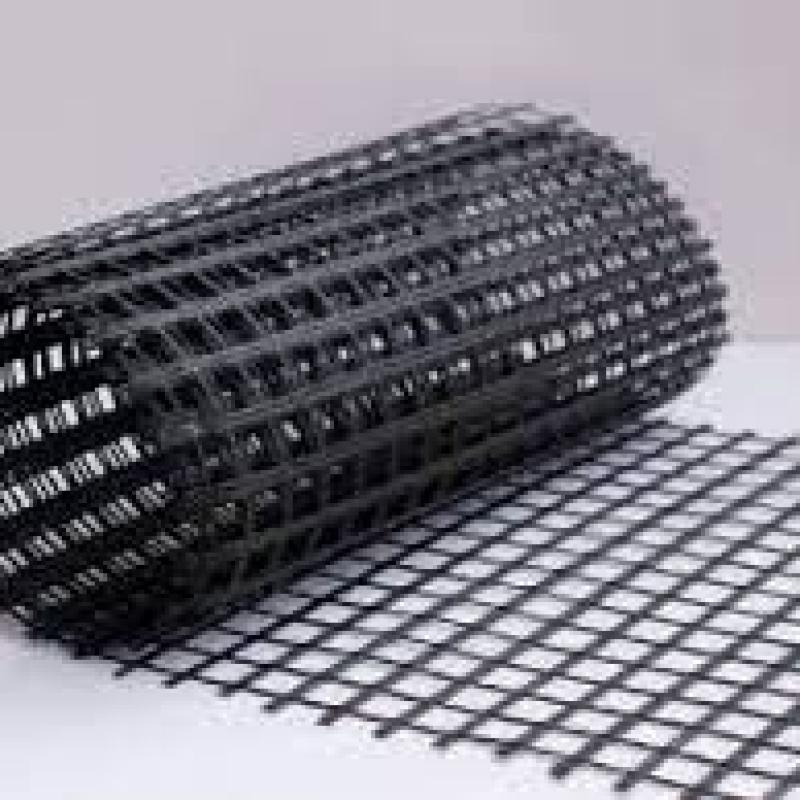

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Contacter maintenant

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Contacter maintenant

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Contacter maintenant

Product DetailsMetallic plastic geogrid reinforcement can correctly complements the bearing ability of foundation and stops the soil from lateral displacement because of its excessive friction coefficient and the bearing capability.

Contacter maintenant

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology.Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Contacter maintenant

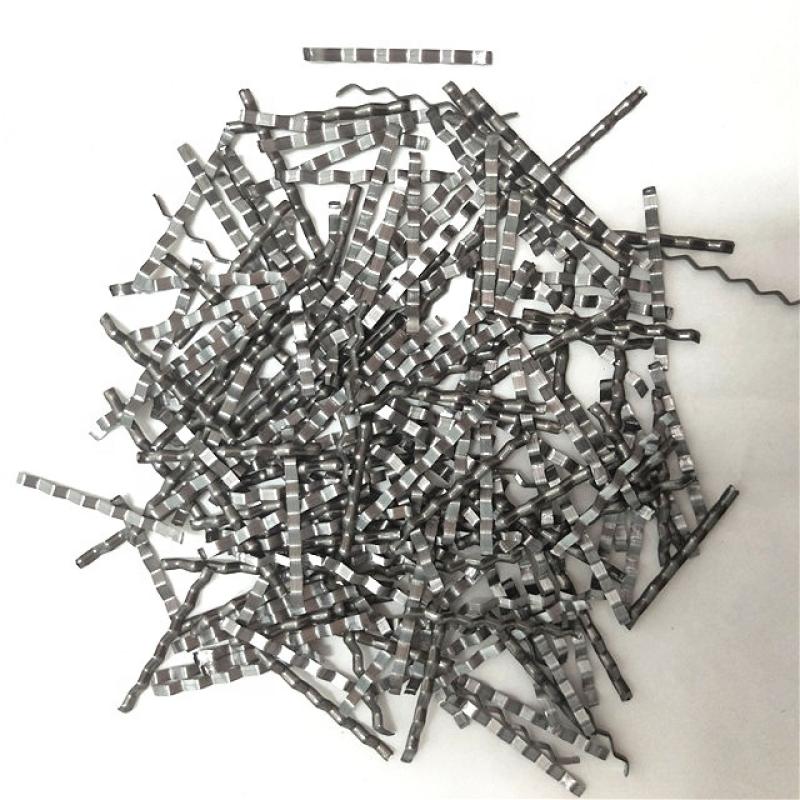

In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.Compared with general concrete, Carton steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness,crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore, concrete strength is improved i

Contacter maintenant

Product DetailsSteel plastic geogrid reinforcement can correctly enhances the bearing capacity of basis and stops the soil from lateral displacement due to its excessive friction coefficient and the bearing capability.

Contacter maintenant

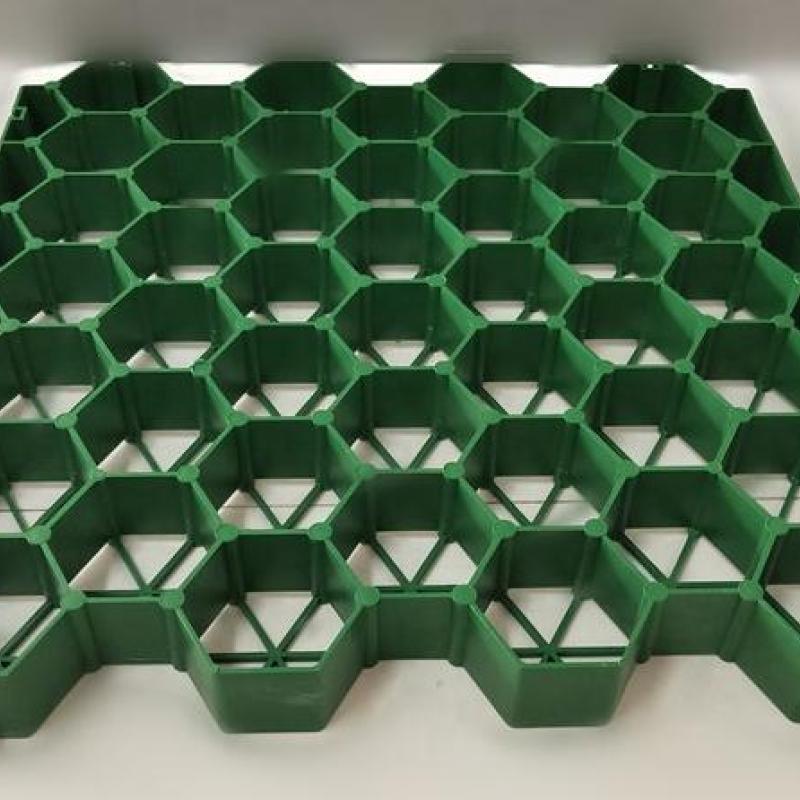

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid in keeping with its structure.Biaxial geogrid is product of polyethylene or excessive density polyethylene as the principle uncooked material thru the tactics of warm-melt extrusion, vertical and horizontal stretching to shape a excessive power reinforced square mesh shape.Uniaxial geogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching.this system makes excessive molecule in direct line country in rectangular oval net shape with uniform distr

Contacter maintenant