Product Details The Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges. In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contacter maintenant

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Contacter maintenant

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contacter maintenant

Product DetailsThe Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges.In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Contacter maintenant

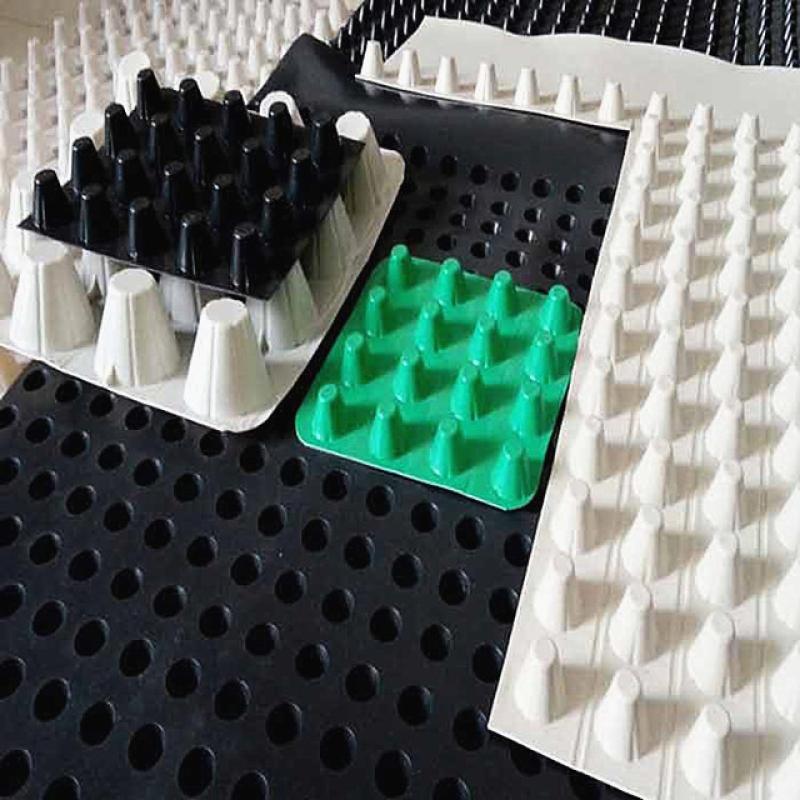

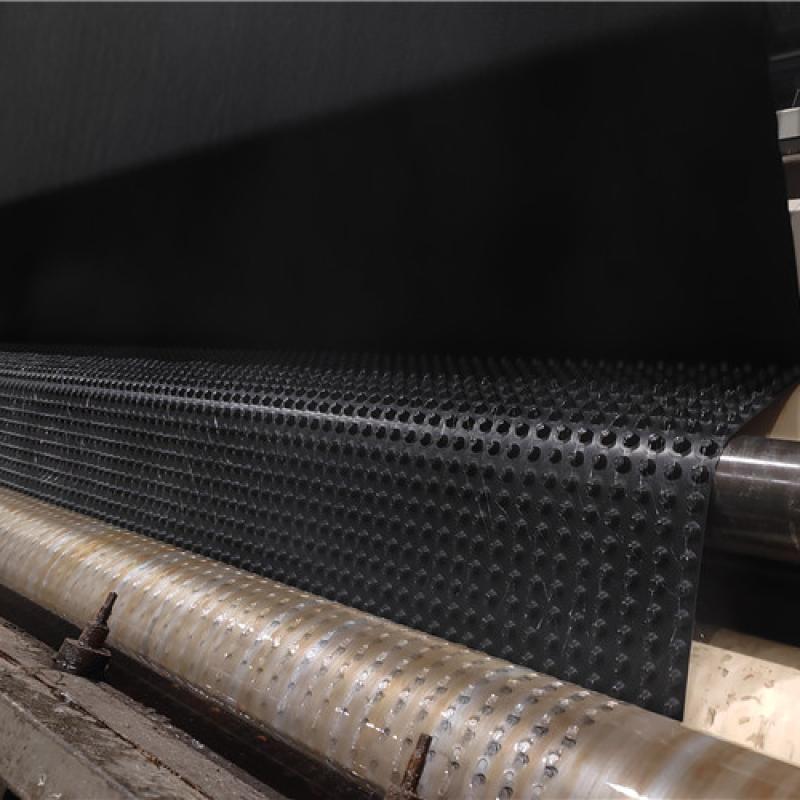

Product DetailsComposite drainage net is made from geonet bonding two layers of geotextile which combines the properties of geotextile filtration and geonet drainage and protection,providing complete“inverted filter drainage to protect”effect.Drainage nets core is extruded by high density polyethylene raw materials adding carbon black and ultraviolet and antioxidant stabilizer.The interlaced net forms into a drainage channel which has good vertical drainage properties.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic ConductivityM/SK*10

Contacter maintenant

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which combines the homes of geotextile filtration and geonet drainage and safety,providing entire“inverted clear out drainage to shield”effect.drainage nets center is extruded by way of excessive density polyethylene uncooked materials adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced net office work right into a drainage channel which has fantastic vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6

Contacter maintenant

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contacter maintenant

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Contacter maintenant

Product information3D Reinforcement Mats Slope Greening Vegetative Blanket / 3D Mat of SoilThe strengthened geomat is pp mesh mat composited with twine mesh, that is galvanized in case of erosion manage.The shape permits enough location for maintaining the soil and grass growing. it's miles malleable to suite the shape changing, and additionally clean to install.It is able to be widely used to road mattress, rail way, slope protection, beach protection & erosion manipulate and channel.ParameterReinforce layer tech dataMaterialUnitppppStandardWeightg/m2500±50500±50EN ISO 965Melting

Contacter maintenant

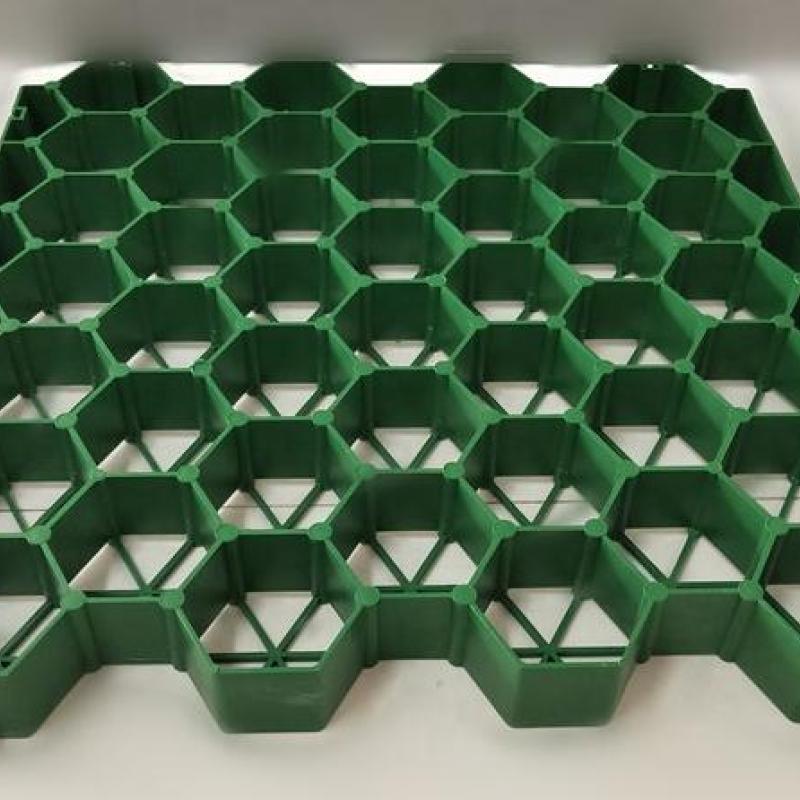

Product Details HDPE Geocell for Road Construction Reinforcement HDPE Geocell is made from a contemporary form of high energy geosynthetic, that is famous with each domestic and distant places, in accordance with Gb/t 19274-2003 implementation of the requirements, which welding the strengthened hdpe sheets with the aid of the excessive-strength ultrasonic and forming. To be a form of 3-dimensional

Contacter maintenant