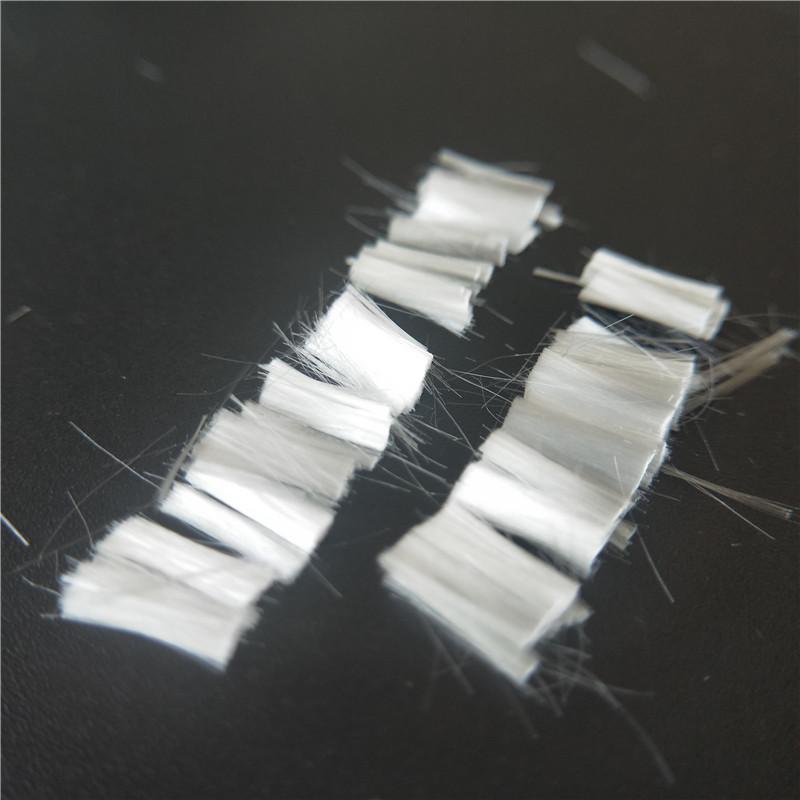

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contacter maintenant

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Contacter maintenant

It‘s the special kind of metal fiber with very high of compressive intensity, tensile intensity, crack resistance.It is widely uesd in high-speed rail precast,RPC cover Board,important projects components and exterior painting. It can improve the performances of the conceret,such as anti-tensile, anti-compressive,shear intensity,impermeability,impact resistance,fatigue resistance,and so on. Tensile Strength > 2800MPA0.2 ~0.3mm diameterLength as your requestApplication Its widely used in highway, bridge, tunnel, airport runway, industrial floor, hydraulic project and bas

Contacter maintenant

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Contacter maintenant

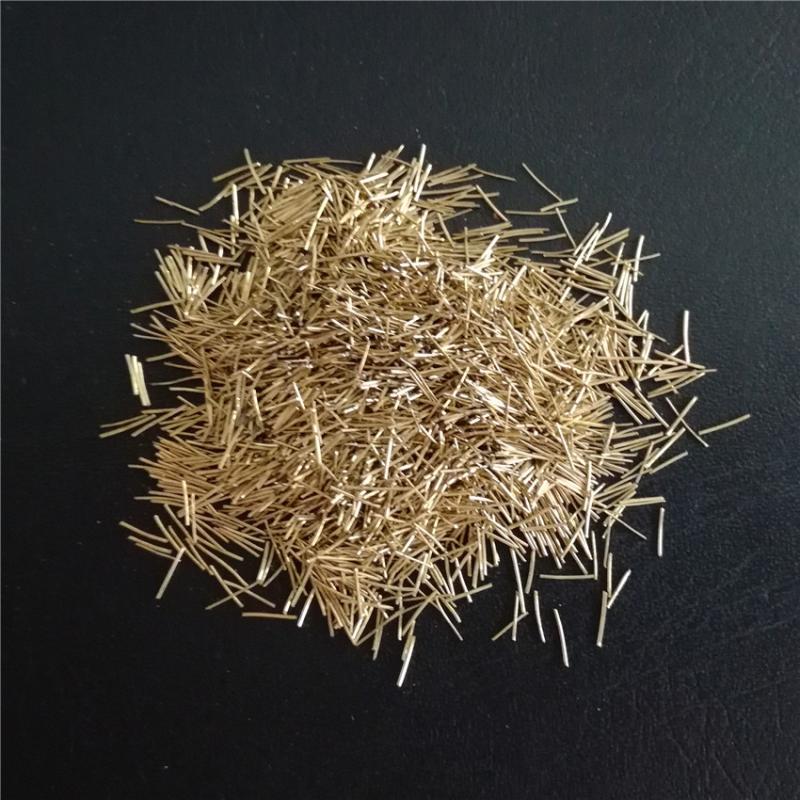

Product DetailsCopper covered micro metal fiber is one among most important substances of rpc ( reactive powder concrete ).RPC has the capabilities of very excessive strength, excessive tenacity, excellent sturdiness and amount stability.Copper Coated Steel Fiber 's miles a amazing and a new kind of manufacturing substances. Micro metal fiber 0.2*13 MM is appreciably used in the building of excessive speed railway, confined-get admission to highway, RPC cover plates and constructional factors.ParameterMaterialCopper coatedTypeStraightLength(mm)5mm-60mmEquivalent Diameter(mm)0.2-0

Contacter maintenant

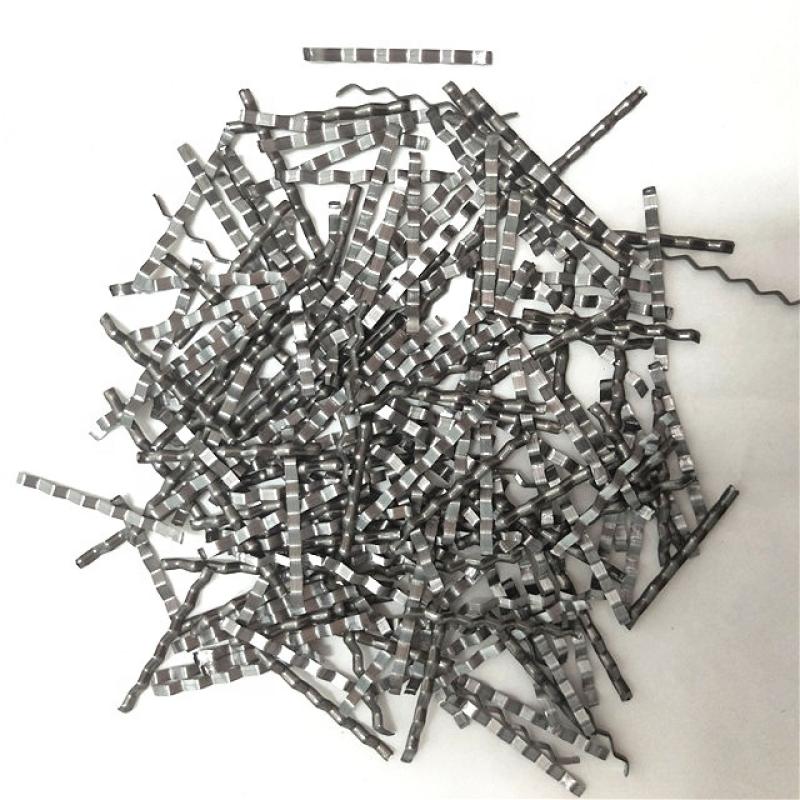

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Contacter maintenant

Polypropylene fiber is also known as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber.We use excessive tenacity polypropylene resin because the raw material and produce with unique technical.Setting the pp fiber into concrete or mortar can manipulate the micro crack because of such elements because the plasticity contraction, air shrinkage and temperature trade.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melting Point160-1

Contacter maintenant

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Contacter maintenant

Polypropylene fiber is also called engineering fiber, concrete fiber, anti-crack fiber, synthetic fiber or plastic fiber. We use high tenacity polypropylene resin as the raw material and produce with special technical. Putting the pp fiber into concrete or mortar can control the micro crack caused by the plasticity contraction, air shrinkage and temperature change.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melting Point160-170℃Acid &

Contacter maintenant

In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.Compared with general concrete, Carton steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness,crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore, concrete strength is improved i

Contacter maintenant