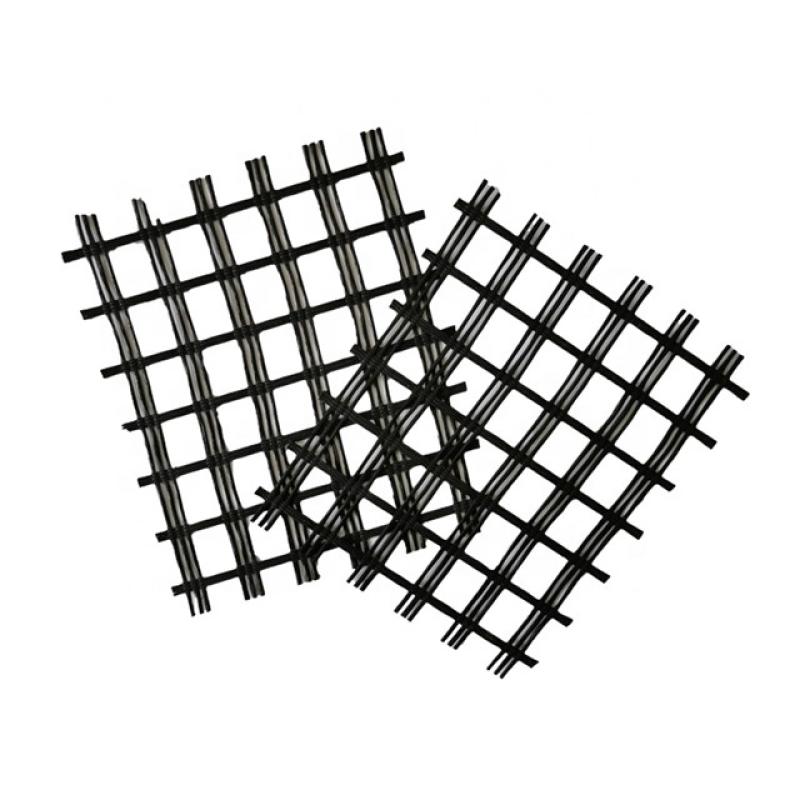

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Contacter maintenant

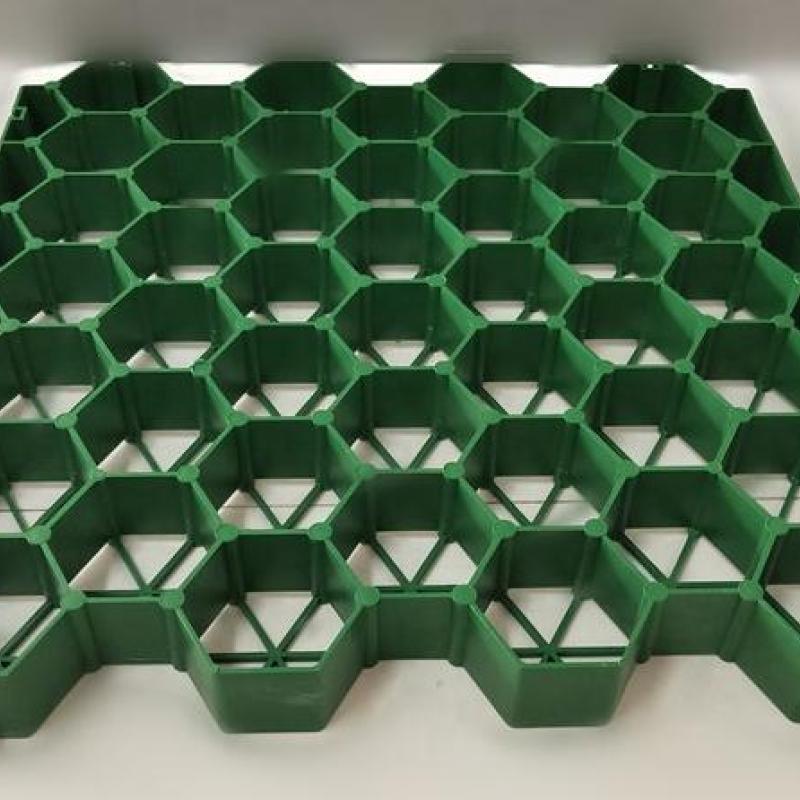

The geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site.

Contacter maintenant

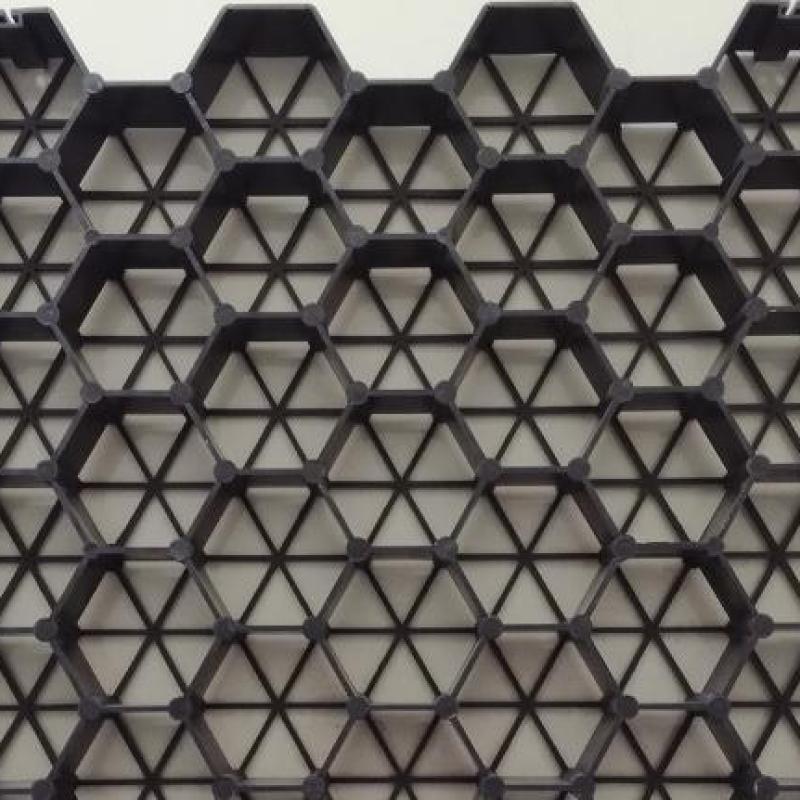

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contacter maintenant

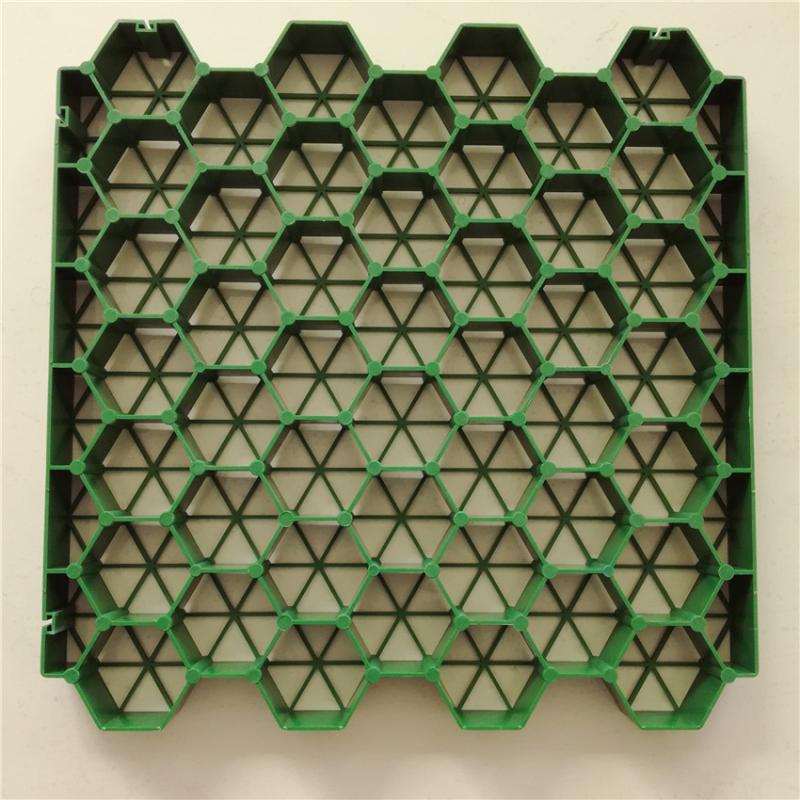

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Contacter maintenant

Product DetailsHDPE Geocell is made of a new type of high strength geosynthetic, which is popular with both domestic and abroad, in accordance with GB/T 19274-2003 implementation of the standards, which welding the strengthened HDPE sheets by the high-power ultrasonic and forming to be a structure of three-dimensional reticular formation which is easily folding and convenient for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,

Contacter maintenant

Product DetailsMetallic plastic geogrid reinforcement can correctly complements the bearing ability of foundation and stops the soil from lateral displacement because of its excessive friction coefficient and the bearing capability.

Contacter maintenant

Product DetailsHdpe geocell is made of a brand new kind of high energy geosynthetic, that is famous with each domestic and overseas, in accordance with gb/t 19274-2003 implementation of the standards, which welding the bolstered hdpe sheets by means of the high-energy ultrasonic and forming to be a shape of 3-dimensional reticular formation that is without problems folding and handy for transportation.When it is be in construction,the HDPE geocell can be pull into a network and launched into a three-dimensional honeycomb grid.As it filled in sol,macadam,concrete or other granular materials,con

Contacter maintenant

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Contacter maintenant

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Contacter maintenant

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Contacter maintenant